|

|

|

|

|

|

|

|

|

|

|

Dry Suspension for

Film Coating

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extended-release

System for Film Coating

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The system through

Pellet

|

|

|

|

|

|

|

|

|

|

Vicegerent Products

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Downlad the PDF DOC of our products to know all

details.

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Normal Moisture Proof(TF-NMP)

|

|

|

This type is

suitable to the tablets that do not absorb vapor quickly such as

those completely or half contains raw plant medicinal medicine.

|

|

|

- Cutting off the

vapor more effectively

- Increasing the

stability and lengthens the storage life of the medicine.

- High mechanical

strength and adhesive of the film membrane

- Filming and coloring

quickly

|

|

|

|

Items

|

Hardness(Kg·N)

|

Breakage(%)

|

|

Tablets

|

4.50

|

0.51

|

|

Ordinarily coated tablets

|

7.23

|

0.31

|

|

TF-NMP coated tablets

|

11.8

|

0.04

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Enhanced Moisture Proof(TF-EMP)

|

|

|

With the

characteristics of simple preparation, quick coloring and great

capability of moisture proof, This type is suitable to the

tablets that need to isolate the vapor strictly such as those

that completely contains concrete of TCM.

|

|

|

|

|

|

Unique formula

- Selecting high

polymer material of special moisture-proof performance and

matching with other many kinds of high polymers material

- Firmer film membrane

- Higher transmission

resistance of vapor

Isolation function

- Higher transmission

resistance of vapor that can protect the tablets from

breaking、inflation

or distortion.

- Increasing medicine

stability and lengthening the term of validity of medicines.

- During guarantee

stronger isolation of water vapor, the membrane keeps high

mechanical strength and adhesion, and dispersingh rapidly.

- The lake pigments

used cannot be influenced by the moisture absorption

ingredient of medicines and the color can maintain longer .

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Instant Disintegration(TF-ID)

|

|

|

|

It is usually

used in oral solid dosage form that has the requirement of

disintegration.

|

|

|

- Protects the tablet

cores and colors

- Film membrane

disintegrate instantly

- Be suitable for the

dispersing tablet and buccal tablet of TCM

Unique formula

- Use special formula

design and advanced preparation process

- Film membrane

harmonizes with sense of the taste, touch and smell of the

tablet cores

Instant disintegration

- Increase

disintegration of the film membrane and the dissolution rate

of the API

- Dissolve instantly

when in mouth and have little feeling of membrane

Superior performance

- Increase the

stability and lengthen the storage life of the medicine

- Film and color

quickly

- High mechanical

strength and adhesive of the membrane

|

|

|

|

Items

|

TF-NMP

|

TF-ID

|

|

Buccal tablet

|

60-80s

|

30-50s

|

|

Dispersing tablet

|

100-120s

|

30-50 or no time delay

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Brightness&Luster Ferric Oxide(TF-BLFO)

|

|

|

|

Be suitable for

the oral solid dosage form that have high request of color cover.

|

|

|

- Strong cover ability、few

amount and higher color radiance.

- Take the ferric

oxide series as the color coating

- Ultra glare

brightness, exquisite smooth clothes membrane, and bright

and stable color

- Very big visual

impulse and allure to the consumer.

- Accelerate

disintegration and release compared to common product

|

|

|

|

Items

|

TF-NMP

|

TF-BLFO

|

|

increased weight of coating(%)

|

6

|

4.5

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Enteric System(TF-ES)

|

|

|

|

It can protect

gastric mucosal from influence of irritant medicine and protect the

medicines that are unstable in gastric juice, especially suitable

for the medicines that need to release in specific intestines

spot.

Taking HPMC、phthalate ester

and acrylic resin, adding the plasticizer, the color lake and

other kind of chemical additive, the film membrane has very

strong mechanical strength and dissolves depend on the pH changes

and guarantees medicine to release safely and effectively.

|

|

|

|

Ultra strong protection

- Protect medicine

from corroding of gastric juice, with only 4% increases;

- Dissolve rapidly

when pH elevates ;

- Reduce the poisonous

side effect of the medicine ;

- Provide the

protection in medicine preparation packing, transporting and

storing process.

Detention releases

- Have very strong

resistivity to the gastric juice and high bioavailability;

- The acid-proof

performance and the intestinal released performance is still

superior after long time;

- storing or under the

storing condition of high temperature or high humidity;

- The film membrane

affects release and absorption of the medicine slightly.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THINFILM®Ethylcellulose Aqueous Dispersion(TF-EAD)

|

|

|

|

It is an ethyl

cellulose coating system completely using water as dispersing medium

and used in oral solid extended release preparation. With the

characteristics of highly effective coating, simple operation and

no plastification, it can form an extended release coating

membrane, make the medicine keep releasing and maintain effective

vivo plasma concentration.

|

|

|

|

Unique Formula

- Take the ethyl

cellulose as a polymer, make the ethyl cellulose to micro

particles to dispersing in water and forming a kind of

emulsion.

- Good physical

stability.

- For the medicine

that is sensitive to acid and that have the property of

water affinity, it is your first choice.

Control Release

- Release not keen to

acid or alkalinity.

- Release obey to zero

and have good ruggedness.

- Control release

through the thickness of the film membrane.

Simple Operation

- Complete water

system, no organic solvent.

- Eliminate the

flammable explosive and toxic dangers of organic solvent.

- No special request

to the production equipment.

- With 30% solid

content but still lower viscosity, it reduces the operating

time and simultaneously avoids pot, bridging of tablets.

- Without usage of

plasticizer, the operation is more convenient.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extended-release Drug

Delivery System through Pellet

|

|

|

|

We provide

massive coating products of different functions and colors, as

well as entire dosage formulation.

|

|

|

|

Formula Design

- Based on customers’

requests, we provide the most detailed comprehensive formula

parameter to the skeleton pellet、the

membrane controlled pellet or both unified controlling

pellet.

- Improve the original

formula to achieve the best.

- Provide entire

formula design and the technical support from the laboratory

tries, experimental to the final industrialization

production

Film Coating

- Use different

coating materials to achieve different operation

requirements.

- Simple operation,

gorgeous appearance, low cost and stable quality.

Superior Performance

- It makes the

medicine distribute widely and evenly in the

gastro-intestinal tract, which enhances the bioavailability,

reduces or eliminate medicine stimulating to

gastro-intestinal tract.

- Not influenced by

food transportation rhythm or gastric evacuation.

- Rule of medicine

releases which cannot affect that of the entire preparation

seriously has good ruggedness compared to that of individual

pellet.

- To meet different

needs, pellets of different releasing rate can be filled in

capsule

- Different

compositions of compound capsule have a better stability and

less mutual function between different medicines.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

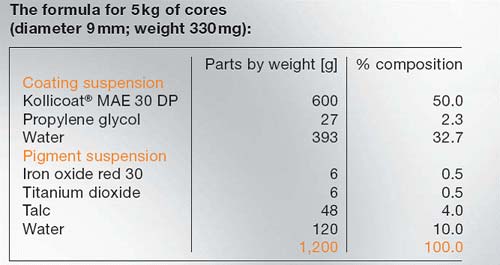

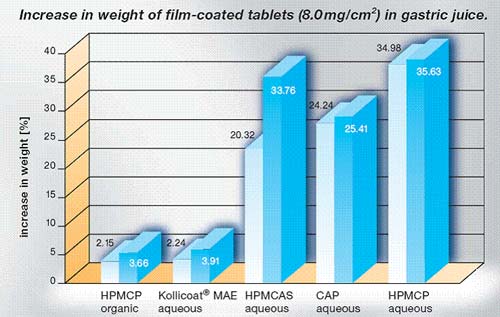

Kollicoat®MAE 30DP

|

|

|

|

Kollicoat® MAE 30

DP is marketed as an aqueous dispersion with a solids content of

30 %. The milky white, low viscosity product has a faint,

characteristic odour. The dispersion contains 0.7% sodium lauryl

sulfate (USP) and 2.3 % Polysorbate 80 as emulsifying agents.

|

|

|

|

Kollicoat® MAE applied in low coating levels,

0.5–2.0mg/cm2solids, can be used for the following purposes:

- Masking unpleasant

tastes and odours

- Protecting

incompatible active substances

- Protection against

atmospheric humidity (short-term)

Kollicoat® MAE applied in high coating levels, e.

g. 10 to 20mg/cm2 is able to protect drugs during long-term

storage against humidity. Even hygroscopic drugs or drugs

sensitive to hydrolysis can be coated with this aqueous

dispersion by using a reduced spraying rate at the beginning of

the coating process.

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

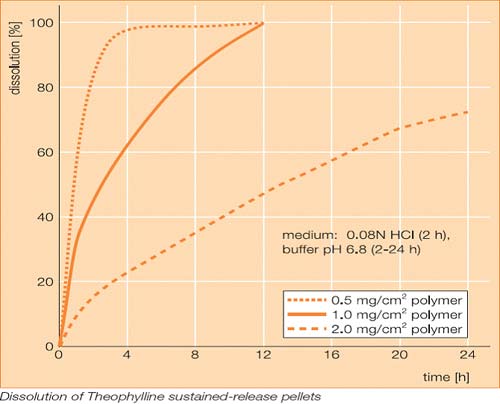

Kollicoat®SR 30D

|

|

|

|

Kollicoat ®SR 30 D is a polyvinyl acetate

dispersion stabilized with 2.7% povidone and 0.3%sodium lauryl

sulfate, with a sol ids con tent of 30%. The dispersion is suit

able for the manufacture of pH independent sustained- release

formulations. The dispersion can also be used for taste

masking.

Kollicoat ®SR 30 D is miscible with water in any ratio while

retaining its milky-white appearance. Mixing the product with

ethanol or isopropyl alcohol in a 1 : 5 ratio produces a slightly

turbid and some what viscous solution. Kollicoat ®SR 30 D is

insoluble in dilute alkaline or acidic solutions.

Sustained-

release coated formulations

It is used mainly for the manufacture of sustained- release

dosage forms. Very effective control of drug release is achieved

by coating pellets, granules and crystals.

Protective

coats

Applied in small quantities or with hydrophilic additives, it

provides good protection against odour or taste. It can also be

used, for example as a subcoating, for isolating active

ingredients to pre vent inters actions.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Kollicoat® MAE 100P

|

|

|

|

Kollicoat® MAE 100 P is a white, redispersable

powder, originating from the Kollicoat® MAE 30 DP dispersion.

Prior to spray drying the dispersion is partially neutralized

with NaOH. This eases redispersion for the final formulation of

the spray suspension. The product consists of 95.8% copolymer,

max. 2.3 % Polysorbate 80 and max. 0.7% sodium lauryl sulfate.

Kollicoat® MAE provides an effective barrier to

gastric juice which:

- Protects the stomach

from drugs such as indomethacin, diclofenac or aspirin;

- Protects

acid-sensitive drugs,e. g. pancreatin from the contents of

the stomach,

- Increases the

bioavailability of active ingredients so that high local

drug concentrations are achieved in the small intestine

increasing the bioavailability or

- Releases the active

ingredient,e. g. laxatives, at its site of action, the

intestine.

|

|

|

|

|

|

|

|

|

|

|

|

back to top

|

|

|

|

|

|

|

|

|

|

|